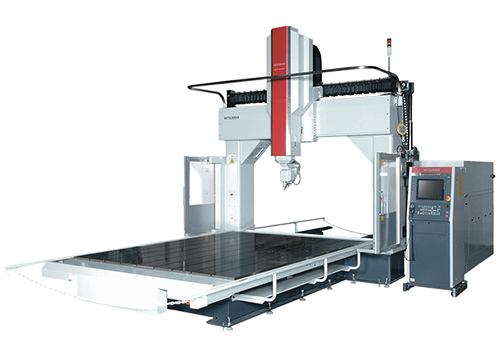

ML1515VZ10

Towards a new type of 3D processing. Challenging unparalleled speed and precision

High-speed processing

Equipped with a Zero-Offset Head with increased critical speeds at corner sections, making high-speed processing possible. The utilization of a new control unit has led to improved processing speeds and faster rotation axes, shortening processing times by up to 40%.(in-house comparison)

Shorter processing time

Mitsubishi Electric’s control system optimizes the laser output power and provides Dross Reduction Control that greatly reduces dross adhesion, minimizing the need for post-processing deburring.

Operability

Simplified teaching box dramatically reduces keystrokes during programming and allows for quicker job setup including program correction.

Product sales enquiry form

Customer Enquiry Form

| Specification | ||

|---|---|---|

| Model | - | ML1515VZ10 |

| Operation Type | - | Hybrid |

| Processing Head Structure | - | Zero offset |

| Control System | - | X-Y-Z-W-U 5-axis, Simultaneous Control |

| Workpiece dimensions (mm) | - | 1520x1520x850 |

| Max. 2D work piece size (C-axis 90° fixed) | - | 1520x1520 |

| Stroke X,Y,Z-axis(mm) | - | 1520x1520x850 |

| Stroke W,U-axis (°) | - | W: ±360, U: ±180 |

| Stroke C,A-axis (°) | - | - |

| Rapid feed rate X,Y,Z-axis(m/min) | - | X, Y: 45 / Z: 35 |

| Rapid feed rate W,U-axis (°/s) | - | 360 |

| Rapid feed rate C,A-axis (°/s) | - | - |

| Max. Cutting Speed X,Y,Z-axis(m/min) | - | 35 |

| Max. Cutting Speed W,U-axis (°/s) | - | 360 |

| Repeatability (mm) | - | ±0.015 |

| Table weight (Kg) | - | 700 |

| Table Pass height (mm) | - | 650 |

| Footprint (reference value in mm) | - | 6300x4250 |

| Machine weight (kg) (excluding oscillator) | - | Approx. 6000 |

| Applicable oscillator | - | ML20XF, ML30CF-R |