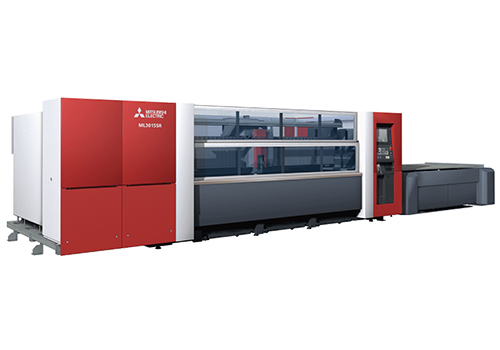

ML3015SR

All-round machine that delivers maximum cost performance on thin to thick sheets

Achieves high productivity with top-quality results

The latest beam control achieves a 40% speed gain in mid-thick plate cutting and allows the SR laser to cut a wide range of material thicknesses.

Delivers an up to 80% improvement in surface-finish quality of stainless steel (t10mm).

Setup time is reduced by up to 70%, improving the efficiency of operation.

Easy and intuitive operation

Offers high-quality laser cutting, regardless of the operator’s skills and proficiency

Reduces operating costs and increases energy savings

Eco mode reduces the power consumption during standby by up to 93%.

Power/Gas consumption monitor supports the visualization of power/gas consumption and energy savings

| Laser Processing Machines Specifiactions | ||

|---|---|---|

| Model | - | ML3015SR |

| Drive System | - | Flying optics (3-axis beam travel) |

| Control System | - | X-Y-Z simultaneous 3 axis ( Z axis height control is also possible) |

| Workpiece dimensions (mm) | - | 3015 x 1525 |

| Stroke X-axis (mm) | - | 3100 |

| Stroke Y-axis (mm) | - | 1565 |

| Stroke Z-axis (mm) | - | 150 |

| Rapid feed rate (combined) XY-axis (m/min) | - | Max. 140 (combined) |

| Positioning accuracy XY-axis (mm) | - | 0.01/500 |

| Positioning accuracy Z-axis (mm) | - | 0.01/100 |

| Repeatability XY-axis (mm) | - | ±0.01 |

| Table Pass height (mm) | - | 880 |

| Footprint (reference value in mm) | - | 12500 x 5150 |

| Machine weight (kg) (excluding oscillator) | - | 7500 |

| Pallet Changer weight (kg) | - | 2100 |

| Applicable oscillator | - | ML32XP |